A couple of weeks ago, I attended the Lean Product Development Implementation Summit, hosted by the Management Roundtable and chaired by Don Reinertsen, author of Developing Products in Half the Time and Managing the Design Factory. Don’s been a big advocate of understanding the theoretical underpinnings of Lean Manufacturing and applying them, sensibly, to new product development. His basic approach, if I can summarize in a single sentence, is to understand the development project’s economics, make sound decisions based on cost/value trade-offs and to engage in practices that encourage the flow of work. Since this is Lean, the goal is to be approximately correctly rather than wasting time trying to be perfect.

The Summit was delivered as a series of case studies, presented by the people actually implementing Lean in new product development (NPD). Presenters came from backgrounds ranging from software development to aircraft design.

It was extremely interesting, and generated a lot of ideas for me. Some of these ideas I have already implemented in my day job; others I’m working with on a longer time-frame, and some I’ve squirreled away for when I need them. For instance, Bernard North, V.P. of Global R, D & E at Kennametal and David J. Anderson, Senior Director of Software Engineering at Corbis, both presented (independent) case studies showing how simple visual controls allowed them and their teams to control both planned work and work in progress, greatly reducing cycle times and accelerating output. In the case of Kennametal, work in progress in the test labs was significantly reduced, eliminating the need to prioritize incoming requests and actually decreasing the amount of work in each request. Within five years, mean lead times were less than twenty percent of previous levels and the percent of revenue from new products had doubled. At Corbis, a very similar visual system enabled them to reduce “hot” requests while greatly accelerating the rate of sofware releases, all by limiting the number of active tasks or projects (applying WIP constraints).

These are two very different environments, but both used essentially the same solution to their problems of cycle time and communication.

Boeing implemented Lean PD, Theory of Constraints and Six Sigma in their development process. If I read the numbers right, it looks like they have cut their development cycle time in half by working to achieve flow in product development and managing projects to the buffers. Other presenters showed how creating very short cycle times (reducing batch sizes) and pushing testing further upstream greatly accelerates product development and reduces design defects.

Another company explicitly re-engineered their new product development process (PDP) around the idea that product development is a learning activity. Their PDP starts with a team meeting in which the goals for the next learning cycle are laid out and the work is divvied up. The team then breaks out for about two weeks to complete the planned work, and completes the cycle with another team meeting, in which they integrate what they’ve learned and plan the next cycle. These planning steps are essentially design reviews, but very explicitly focused on learning and team processes.

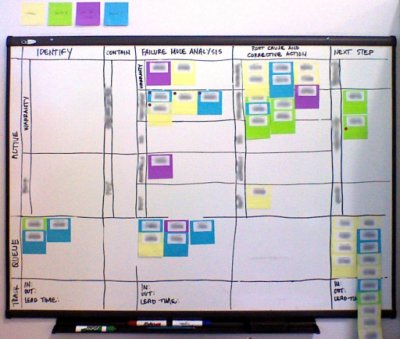

I have now put up a whiteboard for warranty returns, in the warranty processing area. It is divided up according to the phases of our analysis process. Each return is now tracked visually with a sticky note. Queued work (returns that have not been touched) is visible, as are heavy loads on resources. We can now calculate the lead time for our entire process, as well as for major phases within our process. In just a week’s time, the flow of work has smoothed out noticably, and our ability to communicate the status of each return–and problems such as resource overload–has changed from chaotic to dirt simple.

In the past week, we have realized that we also need to track dates, so that we know how old each request is. Our implementation is to simply write the date on the sticky notes each time we move them. This sort of change o.k.; we implemented the system knowing it was not perfect, and that we would improve along the way. This is continuous improvement in action.

There are still clear areas for improvement. One of the big ones is that we still have a push process rather than a pull process. I have not figured out what to do about that, as I have no control over the rate of incoming returns and our customer generally pushes hard to see activity on each return.

Still, this is a simple and effective technique, and can be applied in all areas of R, D & E. One of my long-term projects is the transfer of this technique outside of my sphere of authority.

Presenter David Anderson has posted his own thoughts on the Summit.